Home > Company News > Robotic Welding Environmentally Friendly Workstation

Company News

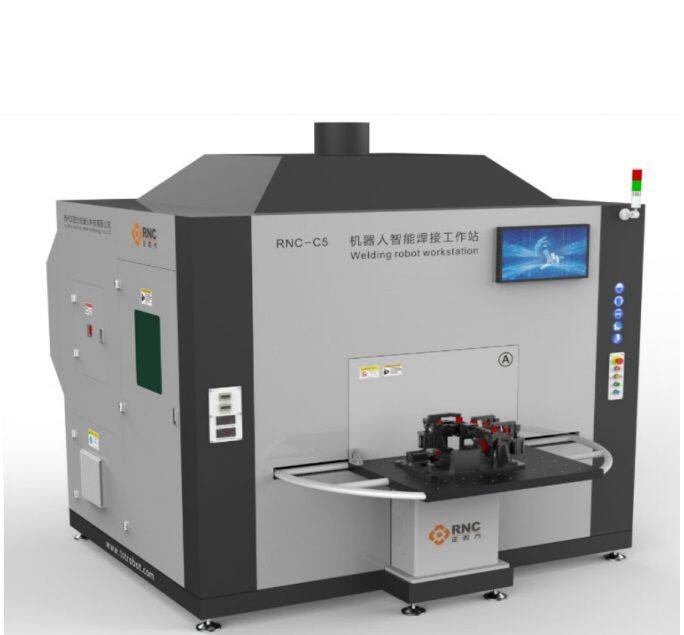

In modern industrial production, robot welding technology is widely used for its high efficiency and precision. However, the smoke and arc light produced during welding pose a serious threat to human health. To effectively control welding dust pollution and the harm caused by arc light to human bodies, it is particularly important to build an eco-friendly robot welding workstation.

Controlling Welding Fume Pollution

Welding fumes contain a variety of harmful substances, such as metal oxides and nitrogen oxides, which, if inhaled over a long period of time, can cause damage to workers' respiratory systems and even lead to occupational diseases. Therefore, it is crucial to effectively control and remove welding fumes.

High-vacuum welding fume capture technology: This is a new type of dust control technology that uses a smoke-extraction port at the front of the welding gun to follow the source of welding fumes and capture them effectively. It can be used without interfering with welding machine operation, without affecting welding worker operation, and ensuring welding quality, while effectively controlling the source of welding fumes. The smoke is collected within 1 second of its generation, effectively solving the problem of welding fume pollution.

Robot Welding Dust Collection System: This system integrates advanced suction, filtration, exhaust and intelligent control technologies, which can capture, efficiently filter and harmlessly treat the welding smoke generated during the welding process in real time. For example, the Livi Environmental Protection Robot Welding Workstation Fume Purifier can effectively remove harmful substances from welding fumes, improve the air quality in the workshop, and protect the health of operators.

The welding room configuration: The robot operates in a relatively enclosed workshop, where a ventilation outlet and a dust removal system are connected at the top of the workshop. The smoke generated during welding is drawn through the top ventilation outlet into the pipe, and then it is treated by the dust removal system and discharged as air that meets the standard.

The harm caused by welding arc flash to human body

Welding arc flash radiation mainly includes visible light, infrared rays, and ultraviolet rays, which can cause thermal, photochemical, or ionizing effects on human tissues, causing damage to human tissues. Effective protective measures must be taken to protect welders' eyes and skin.

A face shield with special protective lenses: A welding helmet must be equipped with a face shield with special protective lenses. These lenses include absorptive filter lenses, reflective protective lenses, and color-changing eyewear. These lenses can reduce the intensity of the arc light, filter out ultraviolet and infrared rays.

Wear special safety equipment: Workers should wear special safety equipment, such as safety glasses and masks, to prevent harm to their eyes and skin from arc flashes.

Set up barriers and reduce reflections: When multiple welding machines are in operation, an unflammable or flame-retardant barrier should be set up; absorbent materials can be used on the interior walls of the workspace to reduce the reflection of arcs; proper lighting should be provided to ensure visibility of the welding area and prevent the need for welders to wear face shields after starting a weld.

Conclusion

By adopting high-vacuum welding fume capture technology, robot welding dust removal system, and special protective lens face shields, it is possible to effectively control welding fume pollution and arc light harm to human bodies. These technologies not only improve the safety and environmental protection of welding operations but also ensure the health and productivity of workers. Building an environmentally friendly robot welding workstation not only enhances the social responsibility of the enterprise but also provides employees with a safe and healthy working environment.